Sustainment Technologies Office

Director: Dr. Greg Hudas

MISSION: Accelerate the development and adoption of advanced technologies and processes for sustainment applications across the DoW Enterprise

VISION: Provide a comprehensive and evolving portfolio of R&E enterprise solutions to enable rapid implementation aligned to A&S objectives through:

- Awareness of state-of-the-art technologies

- Establishment of “advanced” workforce competencies

- Business awareness for ROI in high mix/low volume environments

- Transitions to a resilient supply chain

CHALLENGES: Identification and “derisking” of technologies suitable for sustainment community awareness and implementation

GUIDING DOCUMENTS: DoDI 5000.93, DoDI 5000.94, DoDI 5000.97, National Defense Strategy, National Defense S&T Strategy, National Defense Industrial Strategy

STO Technical Priorities FY25-26

Awareness, Identification and ‘Derisking’ Advanced Technologies

-

- Advanced Manufacturing

- Automation and Robotics for Processes

- AI and Data

- Advanced Materials R&D and Implementation

- Casting/Forging

- Corrosion

- Autonomous Experimentation

- Prototyping, Experiments, Exercises

- Advanced Manufacturing

Supporting a Resilient Ecosystem

-

- Transition and partnerships within Supply Chain

Workforce

-

- Studies and Analysis

- Continuation of IAAAP initiative into Anniston (or other)

- Identification and awareness of competencies

- Understanding of geographic

- Studies and Analysis

STO Focus Areas (FY25/26)

Battle Rhythm:

-

- Liaison and coordination among Combatant Commands, military depots, and sustainment performers in analyzing inputs that define the sustainment gaps and opportunities gleaned from wargames, exercises, and OPPLANs, to inform the direction of S&T efforts and drive requirements

Planning:

-

- Collaborations with J4, Office of the Deputy Assistant Secretary of Defense (Materiel Readiness), and the Services to support the Advanced Manufacturing and Repair Initial Capabilities Document (ICD)

- Initial collaborations with J7 to feature advanced manufacturing technologies in exercises based on ICD

- Maintain continued awareness via the Advana A2ET Environment (JCOP-D) showing relevant MII and Commercial Technologies for Maintenance Activities (CTMA) project portfolios and activities

Continuous Engagement:

-

- DoW Manufacturing Innovation Institute projects that have demonstrated success and/or been transitioned into the organic industrial base

- The organic industrial base comprises the network of Government-owned depots, arsenals, and ammunition plants that provide critical support to military operations

- ST Futures: Ongoing engagements with Advanced Materials and Biotechnology for technologies that can be applied to sustainment gaps and problems

- DoW Manufacturing Innovation Institute projects that have demonstrated success and/or been transitioned into the organic industrial base

STO in Action - 1

Mobile Robotic Defastening

Technology: AI to ID, classify fasteners, for improved and faster drilling operations

Impact: 10x labor reduction, 3x cycle time reduction, reduced operator fatigue / injury

Transition: In use at WR-ALC for F-15 wing disassembly; potential for any weapon system

Mixed Reality Cloud

Platform for Robotics

Technology: Precise, scalable, secure mixed reality for 3D model capture

Impact: 10x cost savings (compared to typical scanners), 10x time reduction in aircraft paint taping, 10x time reduction object localization for laser de-paint,

Transition: In use at WR-ALC, OC-ALC, NAVSEA, NAVAIR, and Letterkenny Army Depot, as well as three commercial sites.

STO in Action - 2

Uniform Work Robotic Sanding on F-35 Canopy

Technology: Multiple Robots with advanced path planning and digital inspection.

Impact: 80% improvement in first pass acceptance. Eliminates 80% of polish defects and rework. Reduces production time by 30%, scrap by 50%

Transition: Targeted transition at WR-ALC. Current experiment at GKN Aerospace. Will mimic at multiple F-35 maintenance sites

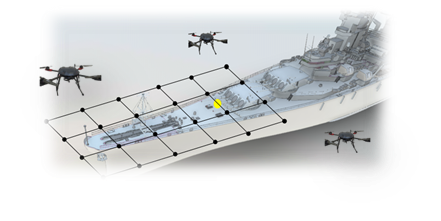

Technology Success – ASIIMOV

Autonomous Swarm Inspection & Interactive 3D Modelling with Orchestrated Visualization

Problem:

- Inspection of large structures is a manual process: time, cost, safety concerns

- Emerging UAV-based methods need extensive preparation, skilled pilot control and data processing; need days to complete a full task

- Need “Inspection software stack” that can be used for advanced service capabilities and inspection for: Shipyard operations (e.g., ship hulls), Hangar operations (e.g., automated aircraft inspection), Energy infrastructure (e.g., power plants), and Large field machines.

Approach:

- An inspection kit for agile deployment in remote / complex environment

- Autonomous swarm allow operator to focus on inspection instead of UAV piloting

- Mixed reality & HMI provide instant feedback to ensure the quality of work

- Automated process for repeatable results to improve productivity and performance

- Interoperable open SW/HW design allow fast adaptation and adoption.

- Benefits: Fully autonomous, fast operation, agile deployment inspection kit using swarm of autonomous drones and mixed reality-based human-in-the-loop to significantly advance the inspection technology for large structures / DOW sustainment goals.

Technology Success (In Process)

Uniform Work Robotic Sanding with Intrastage Inspection

Problem: Optical requirements for modern combat aircraft canopies challenge conventional manual sanding resulting in rework

- Path planning on existing robotic sanding systems has irregular material removal, deep scratches, and material burning resulting in optical distortion

- “Uniform Work” tool path planning and optimization with intra-step digital inspection is needed to reduce rework, worker fatigue, and injury

Approach: Leverage prior ARM-funded work cells with a final demo at GKN Transparency Systems on the F-35 Canopy

- NIAR: analytically-derived “Uniform Work” tool path based on existing ML optical inspection

- UW: ML optical inspection for sanded acrylic extending prior work on turbine blade inspection

- GrayMatter: advanced tool path and robot trajectory generation with integrating inspection

Benefits:

- Process performance: material removal with an 80% improvement in first pass optical distortion acceptance

- Efficiency: accurate sanding intra-step inspection will eliminate 80% of polish stage defects and rework

- Productivity: effective system creation would reduce canopy production time by 30% and scrap by 50%.